Adress and contact

Adress and contact-

RE-AL AG/SA

F. Oppligerstrasse 19

CH-2500 Bienne 6

T +41 (0)32 343 34 20

info@re-al.ch -

Opening hours Monday to Friday

07.30 – 11.45

13.30 – 17.00

Download

Download-

Herewith you will find some

files to download, mainly in PDF, Word or Excel format : - Delivery terms RE-AL

- Inquiry-form for special reamers

- General catalogue

- New: XL-reamers'flyer

8 recommendations for a successful reaming !

Beware: before reaming, have a look and control our "recommendations for reaming".

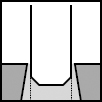

1. Hole oversize

Problems :

- lack of coolant, edge build up on reamers

- irregular angles

- depth of cut too big, reaming tolerance too high

- axial alignment between tool and hole displaced

Solutions :

- correct alignment or use RE-AL floating holder

- check diameter and tolerance of reamer

- check coolant, increase pressure, consider using through coolant

2. Hole too small

Problems :

- reamer is blunt

- depth of cut is insufficient

- workpiece springs back

Solutions :

- exchange reamer

- increase depth of cut

- check coolant, increase pressure, consider using through coolant

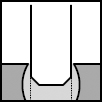

3. Tapered hole (entrance too big)

Problems :

- reamer oscillates in the axis

- drilled hole is not centred

- axial alignment displaced between tool and hole

- swarf in upper part of hole

Solutions :

- correct alignment or use RE-AL floating holder

- ensure alignment of working tool

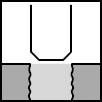

4. Tapered hole (end too big)

Problems :

- axial alignment displaced between tool and hole

- swarf in lower part of hol

- reamer is bottoming the hole

Solutions :

- correct alignment or use RE-AL floating holder

- ensure alignment of working tool

- ream (deep) hole in 2 to 3 passes

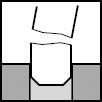

5. Axial displacement

Problems :

- drilled hole is out of axis

- concentricity of lead angle is not correct

Solutions :

- check concentricity of drilled hole

- check concentricity of reamer axis

6. Hole is oval or convex

Problems :

- workpiece moves during reaming

Solutions :

- fix workpiece precisely/constantly

7. Bad surface quality of hole (check also 8)

Problems :

- reamer or hole damaged

- insufficient supply of coolan

- edge build up on reamer

- poor removal of swarf

- axial alignment displaced between hole and tool

Solutions :

- replace reamer

- correct alignment or use RE-AL floating holder

- consult recommendations of reaming

- check coolant and increase pressure, consider using through coolaant

8. Reamer is seizing and breaking (check also 7)

Problems :

- reamer land is too large

- insufficient back taper (min. 0,015 on 100mm)

- drilled hole too small and not centred

- lead angle badly ground

Solutions :

- according to material/spezial alloy adapt lead angle or land

- correct alingment or use RE-AL floating holder

- material dependent (soft/normal/treated) reduce or increase reaming speed